Overview of benefits

- Heat conductive: thermal hot spots are avoided by simultaneously distributing heat via the cooling element and then releasing it to the surroundings

- Flexible: there are virtually no limits in terms of moulding and density, and subsequent processing by means of cutting or punching is unproblematic as well

- Lightweight: 30% lighter than aluminium and 80% lighter than copper

- Resistant: graphite is chemically inert and highly resistant to oxidation and temperatures

- Environmentally friendly: made of natural graphite, free of binding agents

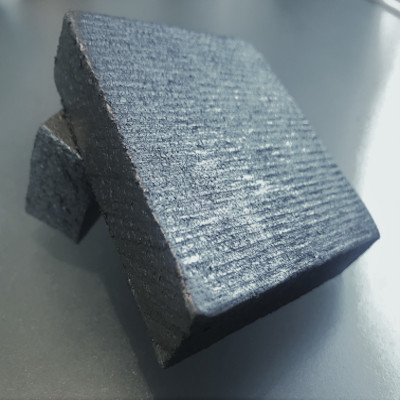

Graphite foams and graphite films are made of expanded graphite and are free of any additives or binding agents. Their density can be freely adjusted to the respective application and they can be moulded in any design. Blocks, rings, sheets, custom components with complex shapes or very thin pressed films are all possible.

The dimensions can be adjusted to the respective application from 30 µm to several millimetres. Graphite foam has numerous benefits. Its advantages compared to metals such as aluminium and copper, still commonly used in heat management applications today, are however the most significant.

We are happy to advise you and help you find suitable graphite parts and/or the right films for your application.

Application Examples for Graphite Molded Parts

Highly effective short-term heat storage

In combination with PCM wax, inexpensive and highly effective short-term heat accumulators are created, which absorb temperature peaks and enable uniform temperature control of sensitive materials such as biological samples etc.

Heat Management

in housings of electronic components, e.g. LED lamps, batteries, etc.

Sealing Rings

are individually adjustable in their dimensions and provide excellent lubrication.

Your contact person

Klaus Rathberger

The right additive or special raw material specification exists for every application. Let’s find the appropriate solution together. Our team and I are happy to help you.