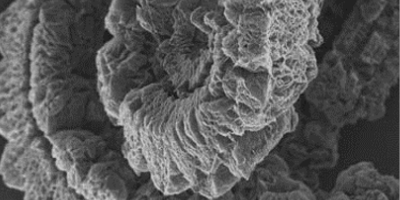

New generation expandable graphite – halogen-free flame retardant for application temperatures up to 270°C

June 2020, by Angelina Schöffel

Expandable graphite has been successfully used as a flame retardant within automotive as well as construction industry for several years now. Established applications include PU foam products as acoustic parts in the engine compartment e.g. within car and aircraft seats. Furthermore, in the construction industry, expandable graphite is used in compounds for the production of fire protection collars, sealing tapes and fire protection doors. Additionally, it can be used within bitumen roofing membranes.

Until now, the starting temperature of max. 230 °C has been limited expandable graphite for the use in high-temperature polymers such as polyamide. With our new generation expandable graphite GHL PX 95 HT 270, we have been able to develop a new expandable graphite quality that shows its protective characteristic from 270°C. Concerning the known product parameters of purity, pH value, particle size and expansion volume, no compromises have to be made with this expandable graphite quality either. Therefore, expandable graphite can now be used for polyamides and applications with processing temperatures up to 260°C.

Since we see particular potential in this new generation of expandable graphite, we have initiated a research project together with the Institute of Polymer Technologyat the University Erlangen-Nuremberg to investigate the effect of expandable graphite in various polymers. Combinations with different synergists such as MDH and APP are also being tested. The main goal of the research project is not only to be able to offer our customers a reliable, halogen-free flame-retardant additive on a mineral basis. Furthermore, our claim is to provide comprehensive support on processing as well as on combination and optimization options to achieve all required fire protection classifications.

You would like to test our expandable graphite GHL PX 95 HT 270? Get in contact with us now! We will gladly answer your questions and support your tests with samples.

Your contact person

Angelina Schöffel

The right additive or special raw material specification exists for every application. Let’s find the appropriate solution together. Our team and I are happy to help you.