Due to its layered structure, graphite exhibits excellent lubricating and parting properties. In contrast to liquid lubricants, it maintains intact even under pressure or at high temperatures. This makes graphite a proven, environmentally friendly and indispensable component, for example in separating agents for metal processing or the production of high-performance lubricating grease. Graphite also shows its strengths as a dry lubricant, especially at very low sliding speeds in conjunction with a high surface pressure.

The requirements that lubricants have to meet vary according to the application. We are happy to help you choose the right product for your lubricating needs.

Advantages of graphite in lubricants

- excellent lubrication and release properties

- resistant to heat, cold, steam and acids

- very good dynamic and static load capacity

- excellent thermal conductivity

- low noise and vibration damping

Lubricant and friction applications

Graphite as a solid lubricant or in dispersion form

Graphite-based solid lubricants are used for lifetime lubrication in industries where grease and liquid lubricants are not permitted. When graphite is integrated into pastes, suspensions or grease, the friction coefficient of the surfaces can be reduced by creating two sliding planes and the service life of components is extended.

Self-lubricating components

Slide bearings and gear wheels are the most widely known self-lubricating components with graphite. Their good abrasion and wear resistance makes the components maintenance-free and they easily withstand dynamic and static loads, even under extreme conditions such as high or low temperatures.

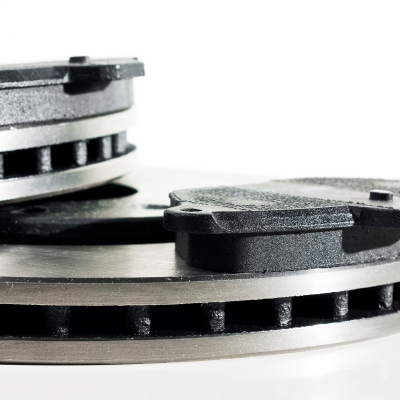

Friction linings and brake pads

The production of friction linings demands an optimal combination of various raw materials. Graphite with its outstanding lubricating effect modulates the friction of friction linings, making a significant contribution to braking comfort and noise reduction. Furthermore, the thermal conductivity of graphite distributes heat evenly and thereby prevents overheating.

Your contact person

Alexander Schleider

The right additive or special raw material specification exists for every application. Let’s find the appropriate solution together. Our team and I are happy to help you.

![[Translate to Englisch:] selbstschmierende Zahnräder](/fileadmin/user_upload/bilder/anwendungen/Zahnrad.jpg)